Application

Pumps, Its type and Industrial Application

Presented By : Mr. Ashwin Patel ( Director- Technical) HET ENGINEERING & PUMPS PVT. LTD. AHMEDABAD

WHAT IS PUMP?

A pump is a device for converting the energy held by mechanical energy into hydraulic energy.

Function :

Properties :

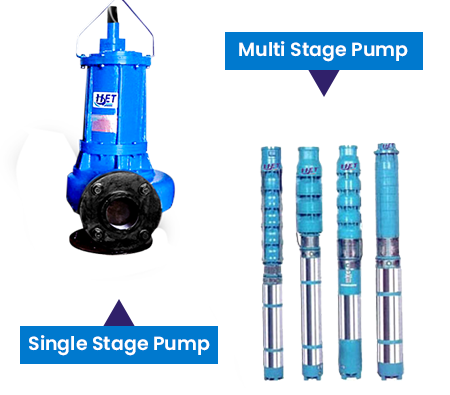

Single stage pump :

Only one impeller is revolving in casing then it is called as single stage pump.

Double / Multi stage pump :

When in a casing two or more than two impellers are revolving then it is called double/ multi stage pump.

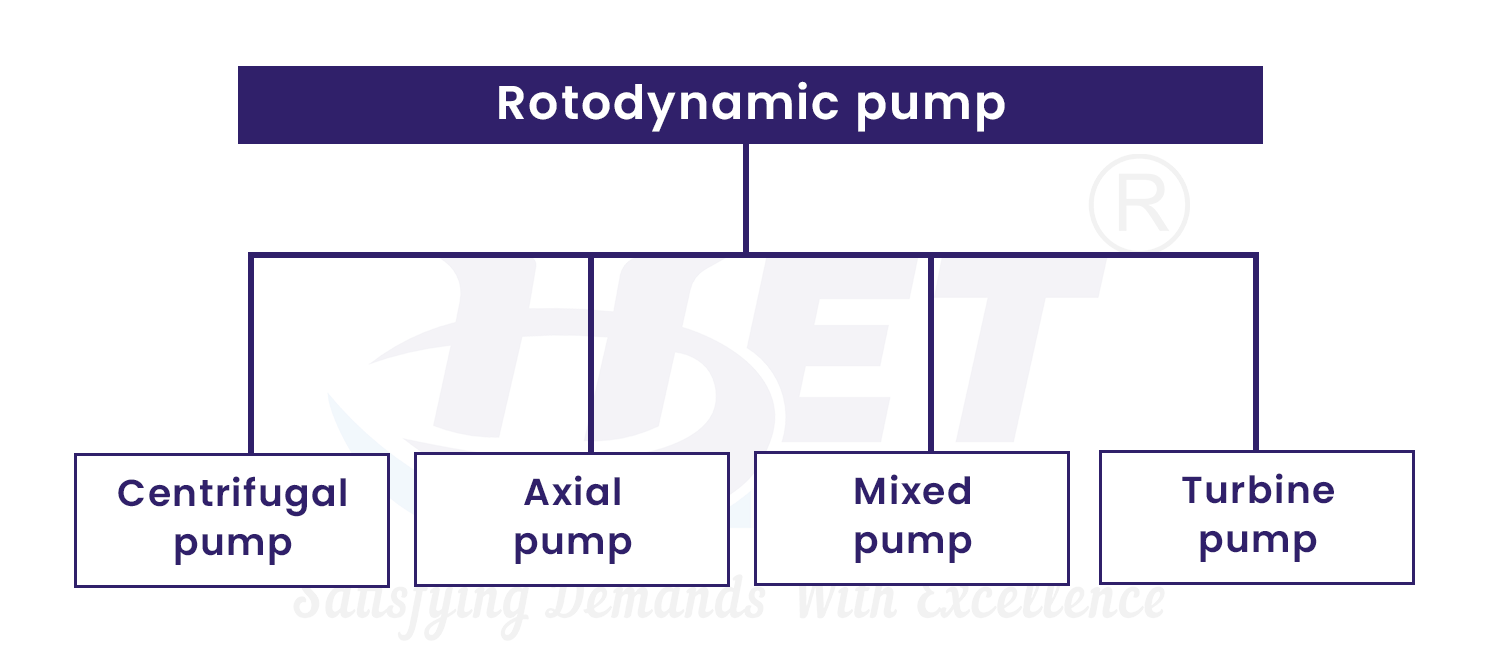

Types of Rotodynamic Pumps

Centrifugal pump

Centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow.

Application :

Oil - refineries, power plants Building Services, Irrigation Chemical and Process Industries Industry and Water engineering

Axial flow pumps

These are also referred to as All fluid pumps. The fluid is pushed outward or inward and move fluid axially. They operate at much lower pressures and higher flow rates than radial-flow (centripetal) pumps.

Application :

In power plants, they are used for pumping water from a reservoir, river, lake or sea for cooling the main condenser

In the chemical industry, they are used for the circulation of large masses of liquid, such as in evaporators and crys

In sewage treatment, an AFP is often used for internal mixed liquor recirculation tallizers

In agriculture and fisheries very large horsepower AFPs are used to lift water for irrigation and drainage

Mixed-flow pumps

Mixed-flow pumps function as a compromise between radial and axial-flow pumps.

The exit is in b/w 0 to 90 angle .

higher pressures than axial-flow pumps

While delivering higher discharges than radial-flow pumps.